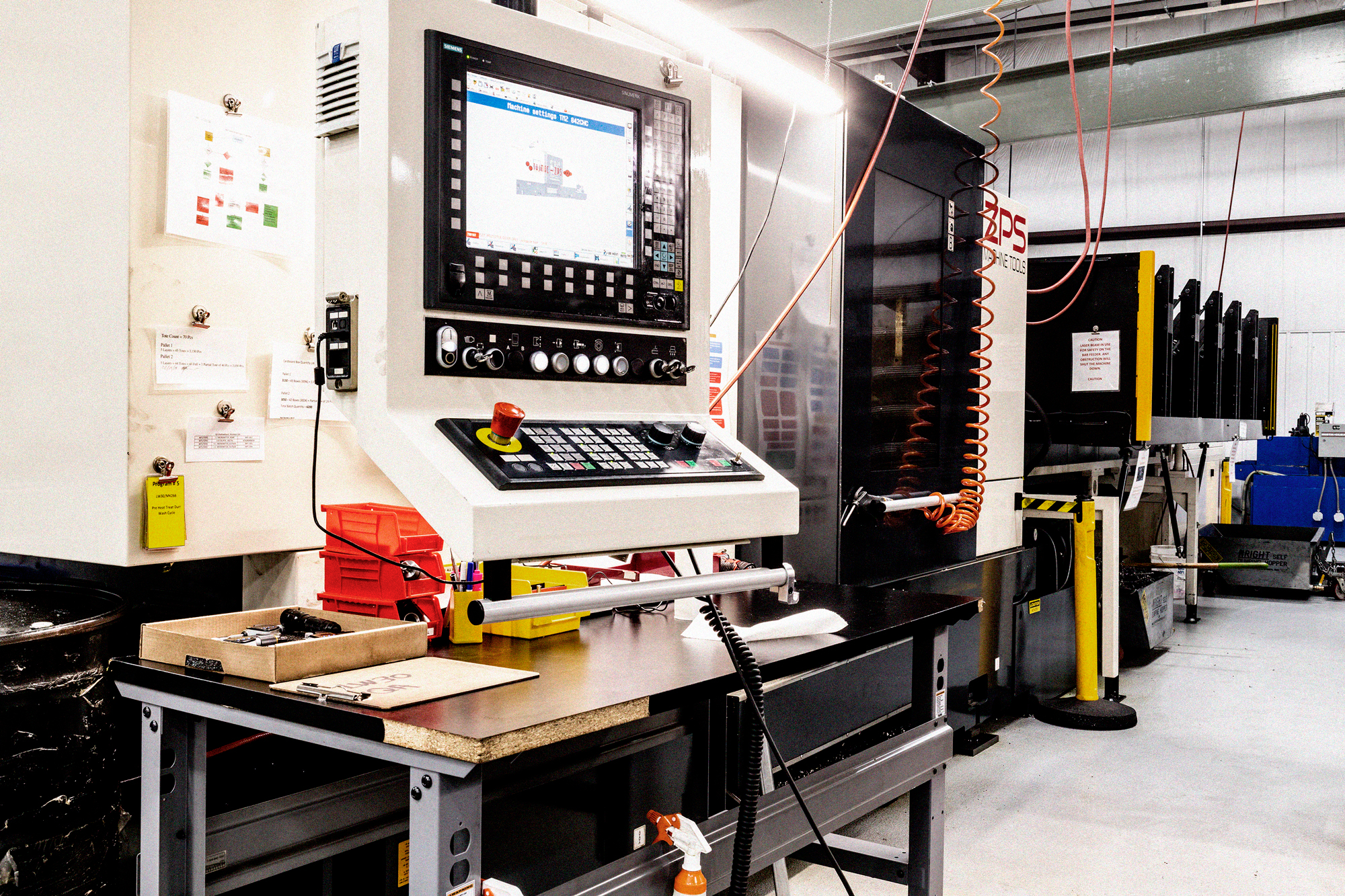

With technology, innovation, and experience, we manufacture firearm and munition components at a rate that is unmatched and unlimited. The caliber and quality of our machines empower us to produce more efficiently and accurately. Our machining practice sets the bar for the industry and makes us a top global manufacturer of BCG and firearm components.

Complete BCGs & Components

We are a primary producer of Bolt Carrier Group (BCG) assemblies for the AR-15 Rifle community. Our customers have the option to purchase complete BCG assemblies as well as the component parts. Our superior equipment and process allow the production of all our BCG components to be made right here in the United States.

MPI provides fully assembled bolt carriers to many leading OEMs in the Modern Sporting Rifle industry.

High-volume Firearm Components

As a high-volume production facility, we manufacture a variety of firearm components and can add varying parts depending on our customer’s high-volume requirements.

Whether our customers need gas blocks, drop-in trigger assemblies, or shotgun or pistol components, MPI sets the standard for high-volume and complex firearm components.

High-volume Defense Munitions

For more than ten years, we have been producing high-volume projectile parts for the defense market. MPI carries strength, knowledge, and a well-known reputation in both the munition and firearm industries. We are a team who understands the stringent quality and regulatory mandates required by the defense industry, and we are always compliant with the demands of the industry.

Our team produces high-volume 20mm – 40 mm projectiles.